Twin Cities Habitat for Humanity’s Global Village Goes to Guatemala

In May 2025, Twin Cities Habitat for Humanity staff, supporters, and volunteers went to Guatemala for a Global Village build week. Keep reading to...

Guest blog by Ann Senn,

Global Village Volunteer

This morning, my husband Mark Ambrosen and I worked at the CEB site making “compressed earth bricks”—a special Habitat Cambodia project. The brick making process is laborious—sand is shoveled into buckets and carried to one of three sifting stations. At the sifting station, the sand is poured a bucket at a time onto a square wooden framed screen where it is scraped back and forth over the screen with paddles to sort out rocks and clumps of clay. Sifted sand is shoveled off the floor back into buckets, then mixed with cement and a little water in a huge basin with a motor driven paddle. After the sand and cement is thoroughly combined, the batch is dumped on the floor and shoveled a bucket at a time into the brick press.

Ann digging sand

Mark at the sand sifting station

Brick press

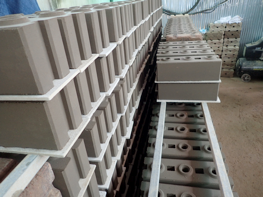

Finished bricks sitting to cure

Habitat Cambodia is introducing CEB (compressed earth bricks) instead of traditional fired bricks because the firing process is harmful to the environment. CEB bricks are also very attractive. While the CEB process is a bit more expensive, the brick becomes cost neutral if the brick is left exposed rather than plastered or mudded (as is the custom with most fired brick walls.)

Brick Recipe

11 large buckets of sand and 1 bag of cement (the amount of water is an art) = 60 bricks,

Brick Production

Our team made 410 bricks after 2.75 hours. It takes about 30 seconds to sift a bucket of sand and the brick machine can press about 4 bricks per minute.

Brick Strength

Well, we can attest to the fact that compressed earth bricks are remarkably hard—harder than any bricks I have ever worked with.

After the adventure at the CEB site, we returned to our build site. The afternoon’s task was to pour a cement floor and the first step was to prepare the interior ground. We scraped debris from the walls and proceeded to smash the construction debris inside (broken bricks and rock) to level the interior ground -- the bricks were almost as hard to break up as the natural stone.

Our house team beginning to mix the cement floor

Pouring the floor was an experience. We hauled sand into the house into piles where we added cement and mixed the two materials with a hoe. The piles were then hollowed out like a volcano, filled with water, and then mixed in place. Skilled workers then spread the cement across the floor with long metal bars. Interestingly, they wore rubber gloves but walked through the wet cement with bare feet.

Worker smoothing concrete

Our blue hat, Piset, explained that floors should be dry by tomorrow morning—that seems almost impossible given the humidity here but he certainly knows what he is doing!

Number of Bricks to a house? We didn’t count… but perhaps 2000-2500.

A shoutout to our small but mighty CEB team of 4 US/Canadian volunteers, 3 skilled local brick makers, and the 4 additional recruits that added great energy to the group about an hour into our shift! A shoutout to the great Habitat skilled workers and Twin Cities Habitat team members for their hard labor in the heat.

And, a shoutout to the wonderful Cambodia Habitat homeowners and community members who delivered waters and wrapped cold waters (with love) around our sweaty necks this afternoon.

I will never look at a brick the same way again!

Learn about our upcoming trips in 2018 to the Dominican Republic and Nicaragua.

Your gift unlocks bright futures! Donate now to create, preserve, and promote affordable homeownership in the Twin Cities.

In May 2025, Twin Cities Habitat for Humanity staff, supporters, and volunteers went to Guatemala for a Global Village build week. Keep reading to...

Eight years ago Sheila Kennedy got an email from Twin Cities Habitat for Humanity about joining a Global Village build in Mexico. The invitation was...

Rebuilding in Haiti since the devastating earthquake in 2010 has challenged the best efforts of relief and humanitarian agencies from around the...